Power Lock

- How to Select The Clamp Lock

1. From table 1 we can get the safety coefficient Lf.

2. From motor input power P (kw) and shaft revolution speed N (rpm) we can get the workong torque Tw.

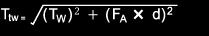

Tw(nm)=Lf×9550×P(kw)/N(rpm)

3. Fa=Lf*Fa If axial force exists.

4. Calculute the combined working torque Ttw

5. Select the right size of clamp lock which T >= Ttw.

Safety Coefficient lf Table 1

Load Smooth Slight Shock Medium Shock Heavy Shock

1.0 1.25 1.75 2.25 - Clamping Sleeve

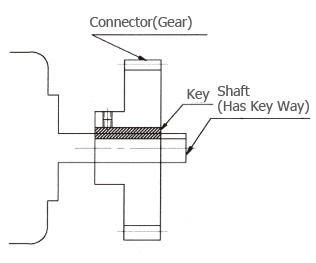

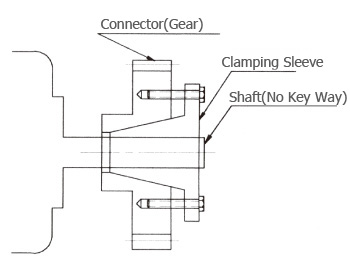

Former use key "with key" Now use clamping sleeve "without key"

The Benefits of Using Clamping Sleeve:

1. Easy to assemble and disas-semble.

2. Material strength of shaft without key way is higher than of shaft with key way.

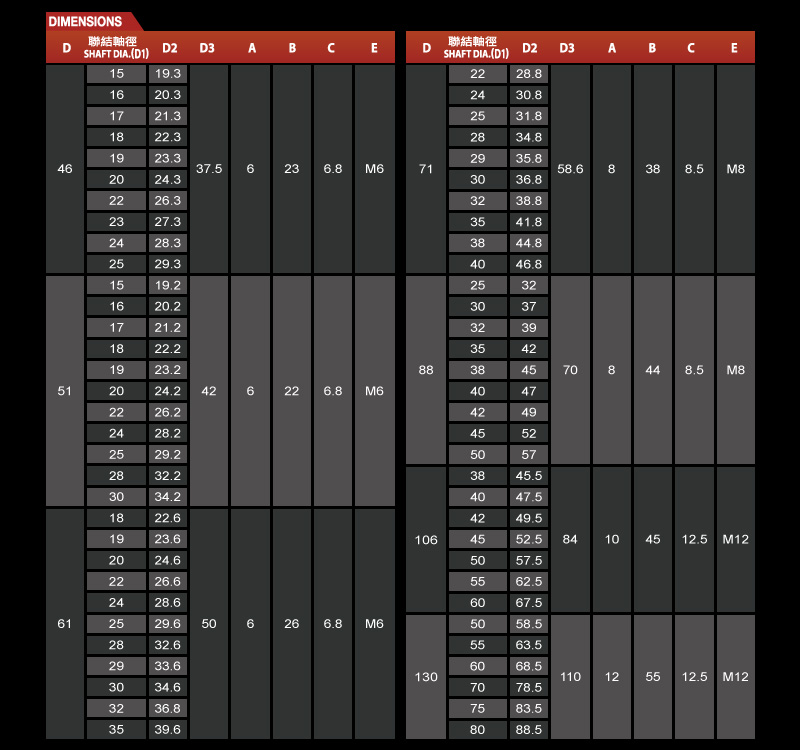

3. We supply many kinds of stan-dard sizes of clamping sleeve as shown in next page.

Note :

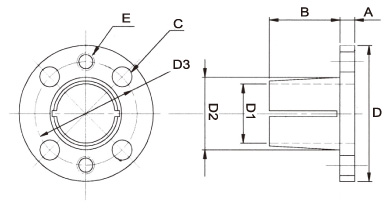

The taper ratio is 1 : 10

(i.e. The taper angle is 2.86°)

Ts(Nm)-Wrench torque. T(Nm)-Transmissible torque due to Ts acting. F(kN)-Axial force due to Ts acting. p(N/mmM2)-Surface pressure acting on the hub.